By Fati Niang, Resource Coordinator, Midwest Services USA

THE REALITY OF TODAY’S LABOUR LANDSCAPE

A Changed Playing Field

Staffing challenges in logistics and warehousing are no longer seasonal, they’re systemic and deeply structural. The post-COVID labour market has shifted dramatically. Many experienced workers exited the industry permanently, some due to long-term illness, others for family care reasons, or higher-paying opportunities in adjacent fields like retail delivery and tech-enabled gig work.

Ongoing inflation has driven up the cost of living, fuel, and food, while wage increases have not always kept pace. Many frontline logistics workers are balancing multiple jobs or reevaluating roles that demand long hours without stability.

U.S. immigration policies have also added pressure, especially in regions where warehousing and transport rely heavily on immigrant labour. With visa backlogs, documentation complexity, and limited access to work authorisation, warehouses that previously filled roles quickly are now experiencing prolonged vacancies.

At one of our partner sites, attendance dropped by 40% within two weeks, not from lack of will, but from a shortage of accessible, reliable labour. The old model of ‘do more with less’ simply broke. What stepped in instead? Structure and systems.

IDENTIFYING THE STRAIN BEFORE IT BREAKS

What Was Happening

Supervisors were onboarding workers while juggling line management. Schedules were handwritten. Communication delays caused packaging errors and unexpected overtime spikes.

What We Implemented

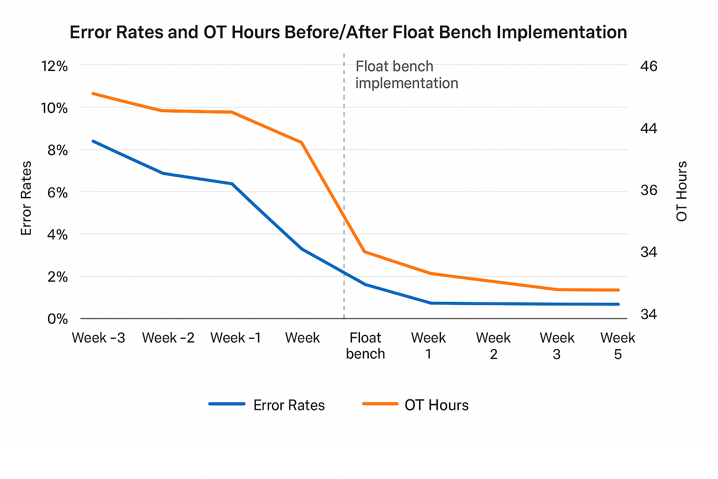

- Operational Relief Pool: We introduced a trained float bench: 6 pre-cleared, certified operatives ready for last-minute calls.

- Lead Sheet System: Supervisors received daily checklists: task orders, shift leads, and backup contact points.

Observed Outcomes

Overtime costs dropped 27%, and fulfilment error rates were halved by week three (Midwest Services data, 2023).

TRAINING LESS, PLACING BETTER

A Shift in Strategy

It wasn’t about the number of workers, it was about matching them correctly. Many temps had never used barcode scanners or handled fragile inventory. Mismatches slowed down production and created tension between temporary and permanent staff.

What We Implemented

- Role-Matched Screening: Candidates were pre-tested on scanner use, pallet loading, and safety awareness.

- On-Floor Micro-Drills: New hires completed 30-minute live simulations before entering primary workflows.

Observed Outcomes

Ramp-up time dropped by 45%. Client satisfaction scores improved steadily over the following month.

THE 2024 REALITY CHECK FOR LOGISTICS LEADS

Your Action Plan

- Build Your Float Bench: Prepare for call-offs, don’t get blindsided.

- Match Experience to Role: The right fit prevents rework and burnout.

- Structure the Workload: Use lead sheets, task briefs, and real-time feedback to keep pace aligned.

THE BOTTOM LINE

Post-COVID, under inflation pressure, and amid complex labour access realities, every inefficiency now carries real cost. Warehousing today isn’t about having enough people; it’s about having the right ones, in the right roles, with the right systems around them. Resilience is no longer optional, it’s the standard.

Need a tailored 2025 staffing strategy?

Let’s talk.